Product features:

1. Light-weighted, with high strength, it is convenient for transportation and installation.

2. With good corrosion resistance, it can transport acidic and alkaline media.

3. With the added wear-resistant agent, it can transport acid and alkali liquids with dust particles

4. The inner wall is smooth without scaling, and the flow resistance is small, saving operating costs.

5. With pipe wall chamber, it has a good waterproof performance, thus producing no secondary pollution.

6. With the added flame retardants, in particular brominated flame retardant resin, its flame retardant grade can be up to B1.

7. Being anti-aging, it has a long service life of 50 years normally for buried pipes.

Connection form: Flat butt, socket insert, flange connection

Areas of application:

1. Municipal water supply and drainage systems

2. Petroleum and chemical sewage systems

3. Seawater desalination pipe network system

4. Circulating water system

Technical Parameters

| DN | 0. 6MPa | 1. 0MPa | 1. 6MPa | 2. 5MPa | Lmax(m) | ||||

| t(mm) | W(kg) | t(mm) | W(kg) | t(mm) | W(kg) | t(mm) | W(kg) | ||

| 25 | 4. 5 | 0. 8 | 4. 5 | 0. 8 | 4. 5 | 0. 8 | 4. 5 | 0. 8 | 1 |

| 32 | 4. 5 | 1. 0 | 4. 5 | 1. 0 | 4. 5 | 1. 0 | 4. 5 | 1. 0 | 1 |

| 40 | 4. 5 | 1. 2 | 4. 5 | 1. 2 | 4. 5 | 1. 2 | 4. 5 | 1. 2 | 1 |

| 50 | 4. 5 | 1. 4 | 4. 5 | 1. 4 | 4. 5 | 1. 4 | 4. 5 | 1. 4 | 4 |

| 65 | 4. 5 | 1. 8 | 4. 5 | 1. 8 | 4. 5 | 1. 8 | 4. 5 | 1. 8 | 4 |

| 80 | 4. 5 | 2. 2 | 4. 5 | 2. 2 | 4. 5 | 2. 2 | 4. 5 | 2. 2 | 6 |

| 100 | 4. 5 | 2. 8 | 4. 5 | 2. 8 | 4. 5 | 2. 8 | 5. 0 | 3. 2 | 6 |

| 125 | 4. 5 | 3. 5 | 4. 5 | 3. 5 | 4. 5 | 3. 6 | 6. 0 | 4. 8 | 6 |

| 150 | 4. 5 | 4. 2 | 5. 0 | 4. 7 | 5. 0 | 4. 7 | 6. 5 | 6. 2 | 6 |

| 200 | 5. 0 | 6. 3 | 5. 0 | 6. 3 | 6. 0 | 7. 7 | 8. 0 | 10. 4 | 6 |

| 250 | 5. 0 | 7. 9 | 6. 0 | 9. 3 | 7. 0 | 11. 2 | 9. 5 | 15. 4 | 10 |

| 300 | 6. 0 | 11. 4 | 6. 0 | 11. 4 | 8. 0 | 15. 4 | 11. 0 | 21. 4 | 10 |

| 350 | 6. 0 | 13. 2 | 6. 5 | 14. 3 | 9. 0 | 20. 2 | 12. 5 | 28. 3 | 10 |

| 400 | 6. 5 | 16. 4 | 7. 0 | 17. 6 | 10. 0 | 25. 6 | 14. 0 | 36. 2 | 12 |

| 450 | 6. 5 | 18. 4 | 7. 5 | 21. 2 | 11. 0 | 31. 7 | 15. 5 | 45. 1 | 12 |

| 500 | 7. 0 | 22. 0 | 8. 5 | 26. 8 | 12. 0 | 38. 4 | 17. 0 | 54. 9 | 12 |

| 600 | 7. 5 | 28. 2 | 9. 5 | 35. 8 | 14. 0 | 53. 7 | 20. 0 | 77. 5 | 12 |

| 700 | 8. 5 | 37. 3 | 11. 0 | 48. 4 | 15. 5 | 69. 3 | 23. 0 | 104. 0 | 12 |

| 800 | 9. 0 | 45. 1 | 12. 0 | 60. 3 | 16. 0 | 81. 6 | 26. 0 | 134. 3 | 12 |

| 900 | 10. 0 | 56. 3 | 13. 0 | 73. 5 | 17. 5 | 100. 4 | 29. 0 | 168. 4 | 12 |

| 1000 | 11. 0 | 68. 8 | 14. 0 | 87. 9 | 19. 5 | 124. 3 | 32. 0 | 206. 5 | 12 |

| 1200 | 13. 0 | 97. 6 | 16. 0 | 120. 4 | 23. 0 | 175. 9 | 12 | ||

| 1400 | 15. 0 | 131. 4 | 18. 5 | 162. 4 | 26. 5 | 236. 3 | 12 | ||

| 1500 | 15. 5 | 145. 4 | 20. 0 | 188. 1 | 28. 0 | 267. 5 | 12 | ||

| 1600 | 16. 5 | 165. 1 | 21. 0 | 210. 7 | 30. 0 | 305. 7 | 12 | ||

| 1800 | 18. 5 | 2. 8. 2 | 23. 0 | 259. 5 | 33. 5 | 384. 0 | 12 | ||

| 2000 | 20. 0 | 250. 0 | 26. 0 | 326. 0 | 37. 0 | 471. 2 | 12 | ||

| 2200 | 22. 0 | 302. 5 | 28. 0 | 386. 1 | 12 | ||||

| 2500 | 25. 0 | 382. 8 | 31. 0 | 485. 6 | 12 | ||||

| 2800 | 28. 5 | 498. 9 | 35. 0 | 614. 1 | 12 | ||||

| 3000 | 29. 0 | 543. 6 | 37. 0 | 695. 4 | 12 | ||||

| 3200 | 31. 0 | 619. 9 | 12 | ||||||

| 3600 | 35. 0 | 787. 4 | 12 | ||||||

| 4000 | 38. 0 | 949. 7 | 12 | ||||||

Note: 1. The thickness of pipes listed in the table includes 1.5 mm inner liner and 0.2 mm outer protective layer.

2. The pipelines listed in the table are based on internal pressure design. The data are for reference only, The specific circumstances vary depending on projects.

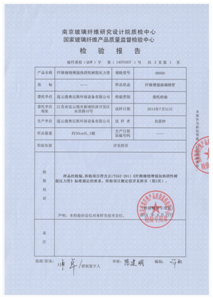

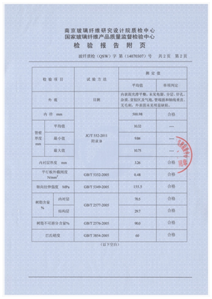

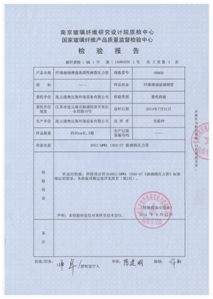

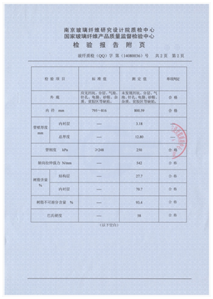

National Testing Reports

|

|

|

|

|

|