ADD Adiabatic Fractional Distillating Demineralizer (hereinafter referred to as ADD equipment) is a new type of highly efficient and energy-saving evaporation equipment, i.e., the "mechanical steam recompression" evaporator. ADD equipment can be used for treatment of high salinity wastewater, desalination of seawater, etc. , and more concentrated in medicine, pesticides, fine chemicals, food processing and other fields. At present, ADD equipment uses the advanced evaporation technology , and is a substitute for the traditional evaporator.

II. Working principle

ADD equipment is an energy-saving technology that uses the steam recompression process, and re-uses the heat of secondary steam generated by the system itself, reducing the external energy demand. Mainly the secondary steam produced by the system is compressed through the compressor, temperature, pressure and enthalpy are increased, re-enter the heat transfer system, and then into the condenser for condensation, making full use of the steam heat. Except start-up, the entire evaporation process requires little or no fresh steam. The steam is fully utilized, the latent heat is recovered, and the thermal efficiency is improved. Evaporation equipment covers a small area, with high degree of automation and ease of maintenance, which can play a very good energy-saving effect.

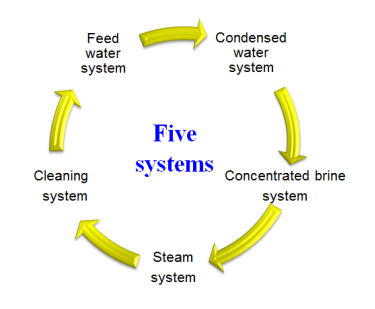

System Composition

III. Scope of application of ADD evaporators

1. Waste water treatment

Concentration of industrial waste water and recycling and reutilization of water, as in: paper-making industry, metal processing industry and enterprises generating high-salinity wastewater, etc.. Discharge and disposal of landfill leachate.

2. Chemical industry

Purification of substances, concentration, crystallization and so on of additives, in various types of chemical industries.

3. Beverage and food industry

In the food processing industry, the evaporative crystallization is used to achieve the dehydration, and the purification and concentration of substances in the beverage industry as well.

4. Pharmaceutical industry

Evaporation, concentration, crystallization and desiccation, etc., as required for production of western medicine

1. Waste water treatment

Concentration of industrial waste water and recycling and reutilization of water, as in: paper-making industry, metal processing industry and enterprises generating high-salinity wastewater, etc.. Discharge and disposal of landfill leachate.

2. Chemical industry

Purification of substances, concentration, crystallization and so on of additives, in various types of chemical industries.

3. Beverage and food industry

In the food processing industry, the evaporative crystallization is used to achieve the dehydration, and the purification and concentration of substances in the beverage industry as well.

4. Pharmaceutical industry

Evaporation, concentration, crystallization and desiccation, etc., as required for production of western medicine